How do you choose dimmable LED light bulbs and how to choose a dimmer?

LED light bulbs isn't resistive load, LEDs are current-driven which means that the intensity of the light they generate depends on the amount of electric current flowing them. Nothing dimmable LED Light bulbs can suitable for all kinds dimmer which use for incandescent bulb. Because incandescent bulb is resistive load, The dimmer for incandescent bulbs is using different way to adjust the voltage. So when you choose dimmable led light bulbs, Be sure know that what kind dimming technology and what kind control protocol of dimmer are used in your lamp fixture. The led bulb which you buy whatever Compatible with your dimmer? Note that Nothing led bulb Compatible with all kind dimmer. Mostly dimmable led bulb for mains voltage operation is Forward phase control dimming (call as triac dimmable led bulb for TRIAC SCR Dimmer), Or PWM dimmable for DC constant voltage operation. Very less dimmable led bulb is Phase dimming compatible with Reverse Phase Control dimming (RFC IGBT Dimmer) and Forward phase control dimming (FPC IGBT Dimmer). If you choose led light bulbs isn't for old dimmer lamp fixture replacement, I recommend that you buy led light bulbs with remote controller or smart led bulb, Almost all remote controller led bulb and smart led bulb is dimmable.

Control protocol of dimmer

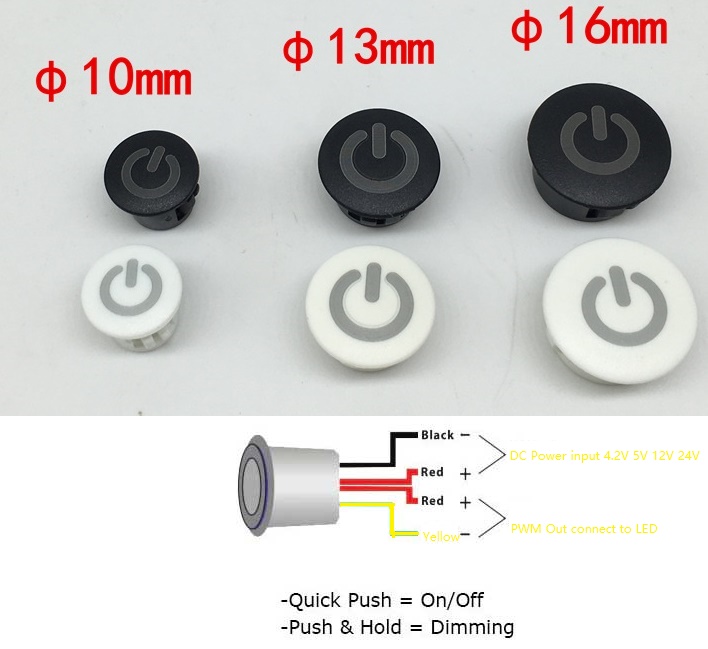

There are different kind control protocol using in AC voltage dimmer, 0-10V dimmer and 1-10V dimmer is an analog lighting control protocol, DALI LED downlights DALI dimmer and DMX512 Decoder dimmer are digital control protocol. But there are converter product on market to convert between analog lighting control protocol and digital control protocol, for example DALI DMX512 Signal Converter, DALI to DC dimmer converter, DALI 0-10v converter. And low cost Dimmer wall switch is non-control protocol, The rotary dial or Slide directly control the time of Triac turned off during the zero-crossing of the waveform, This cheap one dimmer don't have the input / output of signal of 0-10v or digital signal. PUSH Dimming (Switch Dimming, Analogue) A dimming method using a simple retractive (non-latching) switch. The input from the switch to the driver is in addition to the main power supply to the driver. Normally a short push of the switch turns the driver on/off, while a long push dims up and down.

The principle of DC1-10V dimming is also a simple method describing output of driver is fully on i.e. 100% in case the dimming signal is given with 10V externally or just simply make the dimming wires open whereas output level is set at 10% in case the dimming signal is given at 1V. 100% is the maximum of driver and 10% is the minimum level. The dimming response can be found in the figure below.

Dimming technology

There are three kind dimming technology, Triac SCR dimming, IGBT dimming, PWM dimming (call as DC dimmer). Usually the PWM dimming is for the LED light bulb which operation on constant voltage DC power for example DC 12V, DC 24V. The Triac SCR dimming is very popular using in mains voltage operation lighting for example AC 110V, AC 220v, AC 277V, It is cheap than IGBT dimmer. IGBT Dimmer is complicated, Usually using in top quality dimmer.

1. Triac dimmer, SCR dimmer:

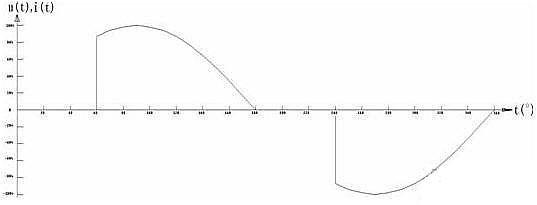

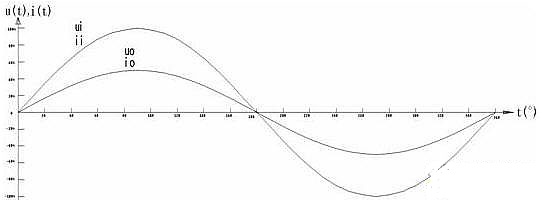

TRIACs or SCRs are used to dim lamps by use of "phase control", This means you turn on the lamp during a certain phase of the AC sine, then back off when at the zero-crossing point. The output wave see below graphical

This type of dimmer is called a "Forward phase controlled" dimmer, Resistive Dimmers (Leading Edge),Incandescent and halogen light bulbs are the most common bulbs where leading edge dimmers are applied. The phase control dimmer has been the dominant dimming technology since the 1960's. Nearly all dimmer commonly mounted in the wall or for desk lamp. The triac dimmer can work perfectly with the incandescent light bulb, but not LED light bulbs (non-dimmable led bulb, But can be for triac dimmable led bulb) or CFL lamp. Triac dimmer cannot drive LED directly ( excluding triac dimmable led bulb ), since LED is not pure resistive load, It needs a LED driver to drive LED. And most of LED driver cannot accept Triac output to adjust LED brightness. So for Triac dimmer, The led bulbs must be special designed, When you choose led light bulbs, Be sure in the description said that it is triac dimmable led bulb for Triac dimmer SCR dimmer.

This type of dimmer is called a "Forward phase controlled" dimmer, Resistive Dimmers (Leading Edge),Incandescent and halogen light bulbs are the most common bulbs where leading edge dimmers are applied. The phase control dimmer has been the dominant dimming technology since the 1960's. Nearly all dimmer commonly mounted in the wall or for desk lamp. The triac dimmer can work perfectly with the incandescent light bulb, but not LED light bulbs (non-dimmable led bulb, But can be for triac dimmable led bulb) or CFL lamp. Triac dimmer cannot drive LED directly ( excluding triac dimmable led bulb ), since LED is not pure resistive load, It needs a LED driver to drive LED. And most of LED driver cannot accept Triac output to adjust LED brightness. So for Triac dimmer, The led bulbs must be special designed, When you choose led light bulbs, Be sure in the description said that it is triac dimmable led bulb for Triac dimmer SCR dimmer.

2.IGBT dimmer: Buy IGBT dimmer MOSFET LED dimmer wall switch from our website for Reverse Phase Dimming Solutions

IGBTs (Insulated Gate Bipolar Transistors) have the ability of being turned off anytime during the phase (TRIACs and SCRs can only be turned off during the zero-crossing of the waveform). Therefore, IGBT Dimmer is complicated, It can be phase controlled dimmer, sine wave dimmer.

a.)FPC IGBT Dimmer and RFC IGBT Dimmer, IGBT Phase controlled dimmer (advanced types of phase control dimmers):

All of Triac dimmer have one thing in common: the phase control waveform is far from ideal for dimming them. In many cases the load will perform poorly; in extreme cases the load (and possibly the dimmer) will be damaged. In the last decade, more advanced types of phase control dimmers have been produced using a type of power semi-conductor called an IGBT.

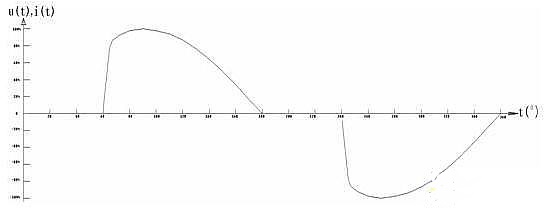

IGBT Phase controlled dimmer can be "Forward phase controlled" dimmer call as FPC IGBT Dimmer and "Reverse phase controlled" dimmer call as RFC IGBT Dimmer.

The output wave of "Forward phase controlled" dimmer is same as TRIAC dimmer. See graphical as below:

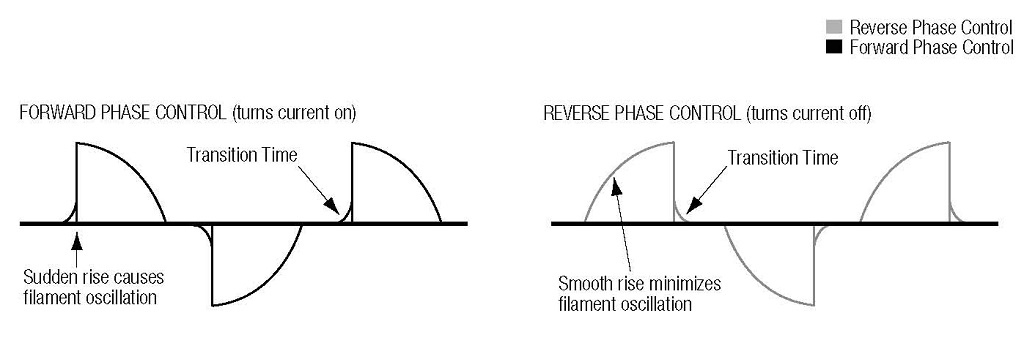

What is reverse phase dimming? "reverse phase control" greatly reduces the EMI of the circuit, along with quieting the light bulb. This approach has just recently been used commercially. Using IGBT drivers allows the dimmer to handle up to 500 W. By using IGBTs to control the lights, the dimming can start on the leading edge of the power cycle. This allows for a smooth turn on/off, thereby eliminating the rapid rise times that produce noise. This design eliminates costly noise filtering and extends the life of the lights by reducing thermal shock.

Reverse phase-controlled dimming of an a.c.-powered load is accomplished by switching power to the load on and off during each half cycle. In one embodiment of the present invention, power is switched on when line voltage is substantially equal to load voltage and off at a selected time later in the half cycle or at any time that the voltage across the switch exceeds a predetermined value. Below is a graphical representation of Forward and the benefits of Reverse Phase Control.

Some of these new dimmers operate in reverse phase control where the dimmer is turned on at the line zero-crossing point, then turned off at the desired output voltage. The bulky choke is eliminated in favor of a controlled turn-off by the IGBT. These systems still suffer from many of the same problems as any phase control dimmer. Reverse phase control dimming applies the voltage to the load at zero volts, and turns it off once the desired target voltage has been reached. This mode of operation is fine for a tungsten (resistive) or electronic low-voltage transformer (capacitive), but is unusable with inductive loads. Neon, ballasted loads, fans and small motors will generate de-structive inductive kickback energy when dimmed by a reverse-phase control dimmer. RPC dimmers must not be used with these loads, or must switch to forward-phase control to dim these loads. In all cases, FPC or RPC, the dimmers are producing triplen harmonics. So for IGBT Phase controlled dimmer, The led bulbs must be special designed, When you choose led light bulbs, Be sure in the description said that it is for FPC IGBT Dimmer or RFC IGBT Dimmer.

IGBT Dimming Technology Features:

Fully Digital Dimming technology with Forward / Reverse phase dimming (automatic or user-selectable)

Compatible with new LED drivers that require reverse phase operation

No dimmer room required and no added cooling needed

Energy efficient - only a 2.5 volt (or less) insertion loss (depends on model)

Solid-state dimming technology with adjustable transition (rise) time up to 1,000 ms for quiet operation

Low Harm mode to reduce neutral harmonics

Automatic Overload Short Circuit protection

Products available for 120V, 277V, or 230V/240V applications

b.)Sine wave dimmer:

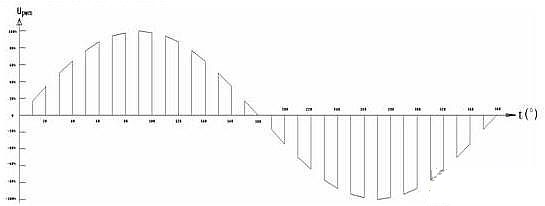

Sine wave Dimmer produce high frequency pulse width modulated control waveforms to the dimmer's IGBT power switches. The 47Khz carrier frequency is divided into 255 steps, providing a voltage resolution on the output of less than 0.5%, resulting in a flawless Sinewave output. The PWM waveforms cannot be directly used to control the load. They must be filtered to produce a Sinewave. So for

Sine wave dimmer, The led bulbs must be sepcial designed, When you choose led light bulbs, Be sure in the description said that it is for Sine wave dimmer. Below is a graphical representation of Sine wave Dimmer.

3. PWM DC Dimmer:

PWM ( Pulse Width Modulation ) : A far superior method of dimming LEDs is to use Pulse Width Modulation (PWM). With PWM strings of LED bulbs can all be driven with the recommended forward current, with the dimming achieved by turning the LEDs on and off at high frequency - so fast the human eye cannot see the strobing effect. The longer the on periods are relative to the off periods, the brighter the LEDs will appear to the observer. Below is a graphical representation of PWM Dimmer. Duty Cycle is a percentage measure of the time that the LED is physically on. If, for example, the LED cycles ON for 9/1000 of a second, and then OFF for 1/1000 of a second, the duty cycle is 90%: 90% of the time it is ON, and 10% of the time it is OFF. Therefore, the intensity of the light will be approximately 90% of its undimmed level.

Advantages of pulse width modulation dimming (PWM Dimming)

1. No chromatographic shift will be generated. Because the LED always operates in the full voltage (on) and 0 voltage (off). The LED is in a fast switching state, if the operating frequency is very low, the human eye will feel flickering. In order to make full use of the visual residue of the human eye, its operating frequency should be higher than 100Hz, preferably 200Hz to 500Hz.

2, can have a very high dimming accuracy. Because the waveform in the pulse can be completely controlled to a high accuracy, it is easy to achieve an accuracy of one in ten thousand.

3. It can be combined with digital control technology to control. Because any number can be easily converted into a PWM signal.

4, even in a large range of dimming, there will be no flickering phenomenon.

Dimming dc led lights, led bulb for extractor pwm voltage

PWM dimming is good for constant voltage LED light bulbs, Because when PWM output high level, The voltage of PWM dimmable LED light bulbs is same as his operation voltage. It will not work with LED light bulbs that with internal driver inside (because mostly LED driver use for control the current of LED, Constant current controlling).

PWM dimmer is low voltage operation dimmer, It can be DC12V PWM dimmer (Operation on DC12~14V), DC 24V PWM dimmer (operation on DC24~28V), or DC12V-DC24V dimmer, 48V PWM dimmer, 48v pwm controller, pwm motor controller 48v, 48v dc motor controller. 36v pwm dimmer, 36v pwm controller, pwm motor controller 36v, 36v dc motor controller. It is used in vehicles of carsm trucks, RVs,Boats, Marine and Aircrafts operate numerous panel lights and convenience lights. So for PWM Dimmer, The led bulbs must be sepcial designed, When you choose led light bulbs, Be sure in the description said that it is PWM Dimmable led bulb for PWM DC Dimmer or not Cobstant current driver inside bulb and choose it is for DC12V or DC24V Dimmer, 36V DC dimmer, 48V DC Dimmer, PWM Dimmer Automatically adapt to DC12-48V working voltage. DC Dimmable LED bulbs combine with DC dimmer is best for application for battery charging dimming lighting system.

Below image is showing how to connect PWM dimmer switch with LED bulb for extractor PWM voltage, You can buy Led bulb for pwm output voltage 12v, 24V, 36V, 48V, 60V and DC dimmer from below link.

14W A22 LED bulb. 12V 24V 36V 48V AC100-277V perfect for DC Dimmer Applications to dimming lighting using battery charge system

8W A19 LED bulb. 12V 24V 36V 48V AC100-277V perfect for DC Dimmer Applications to dimming lighting using battery charge system

4. MOSFET dimmer

MOSFET popular using in smart controller lamp, DALI control lighting or DMX control lights, MOSFET together with MCU which should completely eliminate the EMI.

a.) MOSFET PWM dimmer

The sources of MOSFET are connected together and the gates are driven by an IC or MCU.

The circuit shows that dimmers intended for use at mains voltage do not always have to contain a triac or IGBT, Using MOSFET instead of IGBT or TRIAC completely eliminate the EMI. A MOSFET (for example BUZ41A, 500 V/4.5A) in a diode bridge is used to control the voltage across a bulb with pulse-width modulation (PWM). A useful PWM controller can be found elsewhere.

b.) MOSFET Reverse Phase dimmer

Reverse Phase Dimmer with MOSFETs, The sources of MOSFET are connected together and the gates are driven by an IC or MCU. Due to the power supply of MCU the Vdd is +5V relative to GND, it doesn't matter if GND is at mains voltage AC110V or 240VAC relative to earth, so long as Vdd-GND is 5V, that's what the MCU sees.

Now if you were to touch one of the MCU pins to earth, then the MCU would be destroyed. Similarly if you were programming the MCU using an in-circuit emulator or programmer connected through a USB interface that is grounded, the MCU would be destroyed and possibly much more.

When working with or developing this kind of circuit it's essential to use devices such as a mains isolation transformer or a USB isolator.

While testing we were using a Triac controlled via a MCU and some large inductors to reduce the EMI, but they buzz like crazy. We are investigating Reverse Phase dimming which should completely eliminate the EMI. In this dimmer circuit, Must using a MOSFEET controlled via a MCU and some large inductors to reduce the EMI, Using MOSFET instead of IGBT or TRIAC completely eliminate the EMI. So that Compatible with EMC standard EN55015: 2013 EN61547: 2009 EN61000-3-2: 2014 EN61000-3-3: 2013.

Triac SCR phase Dimmer compatible with LED bulb problem

From here you know that choose dimmable led bulb is difficultly. In fact, Even if you buy a Triac SCR dimmable led bulb, When you install on the fixture which have Triac SCR dimmer (if the Triac dimmer isn't for triac dimmable led bulb), It maybe will flicker. Below are someone say the problem:

The Kaoyi KLT-6021 is a 20-60w rotary dial dimmer for lighting fittings. Suitable for controlling low voltage halogen floor lamps. Kaoyi have discontinued this model, but there is good news. The Huibolong HT6024V2 is identical in every way shape and form to the Kaoyi KLT-6021. Should you purchase the KLT-6021 you will receive the new HT6024V2 in a black case. This model can also be used to replace the Hopestar LC-105, which is identical and the Anchorn AA-3202RVB2. But this unit is still not compatible with LED bulbs. Someone say it is better buy <20 watt dimmer for led bulb.

0-10V 1-10V Dimmer compatible with LED bulb problem

If the lamp fixture has Dylanite 0-10V dimmer wall switch or Lutron 0-10V dimmer wall switch And other Brand 0-10V dimmer wall switch, Be noted that the electronic transformer driver/Ballasts has two kinds:

A. New design transformer driver/Ballasts: The output is DC PWM dimming, 12V led bulb PWM dimmable or 24V LED bulb PWM dimmable and other constant voltage DC dimmable led bulb will compatible with this electronic transformer driver/Ballasts.

B. Old design electronic transformer driver/Ballasts: This is AC output, For increase efficacy while limiting EMI, This electronic ballasts typically operate at a frequency between 20 and 60 kHz., Nothing led bulb is dimmable for this electronic transformer driver/Ballasts, for example ELB Electronics 0-10V T8 Ballasts, Metrolight Smart Electronic Ballasts for HID.

I have a idea that if your lamp is dimmable fluorescent tube or CFL lamp, Remove Ballasts Directly replace with our UL listed SCR dimming 2D fluorescent retrofit, 2G11 2d 4-pin led replacement, As dimmable 2G11 CFL, 2G10 CFL , 2G7 CFL, 2D fluorescent replacement. If you don't know how to do it, You can tell me the control protocol of your dimmer, The watts of you lamp, The size of your bulb. I will help you.

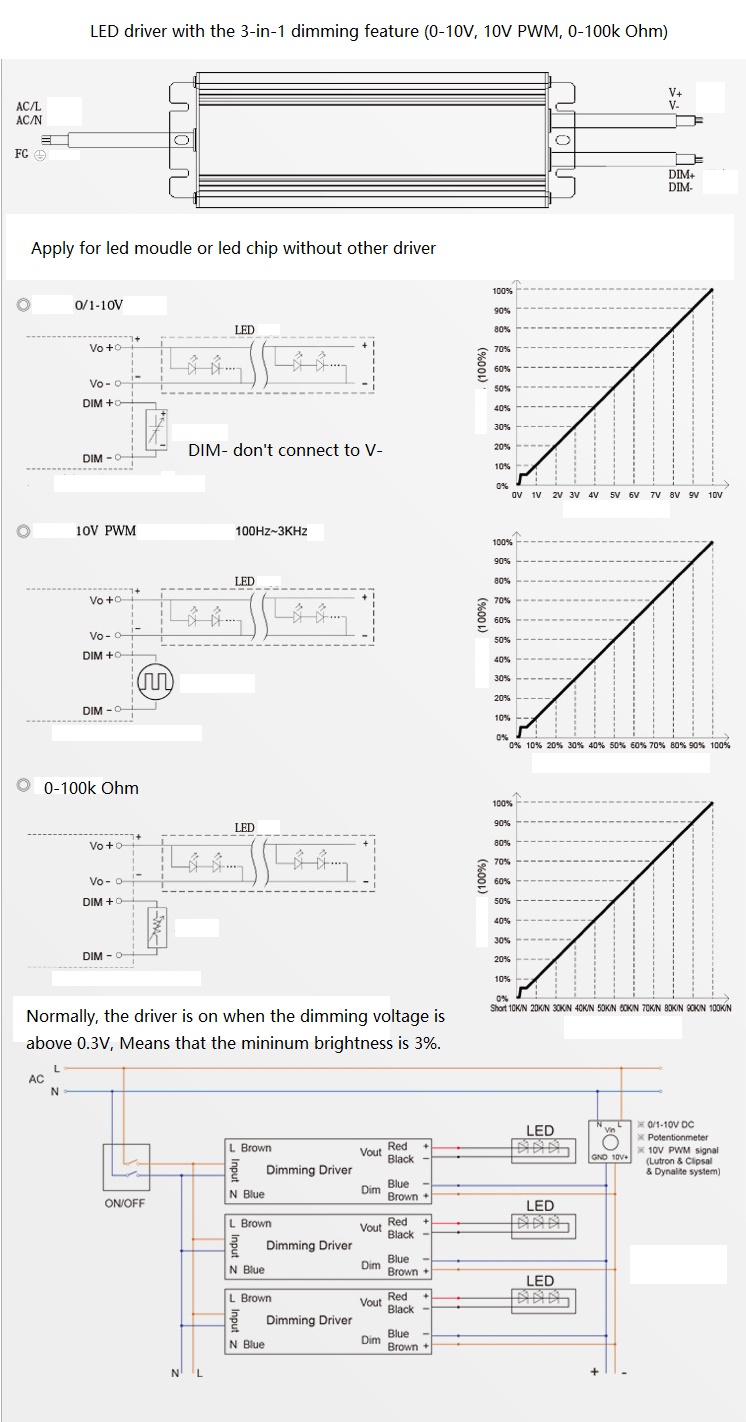

This is a driver for LEDs. It can use for led strip, or a led moudle with no driver inside. The dimmalbe led driver transformer uses 0-10V,10V PWM and 0-100k Ohm input dimming signal to regulate the brightness. The dimming circuitry inside employs an unvarying current source to determine resistance. I have observed 100uA of current flowing through any resistance within the range of 0-100kOhm, according to. Normally, the driver will be activated when the dimming power is higher than 0.3V which means that the minimum dimming brightness is at 3 percent. Below 3% to zero, the driver will turn off. Below will be the dimming 3-in-1 option (0-10V PWM, 10V and 100k Ohm, 0-100k).

Dimmer compatibility test report for 24W ETL listed phase dimming LED bulb 2D fluorescent retrofit 5 CCT Switching change color temperature 2700K-3000k-3800K-4400k-5000k

Test Condition: Vi: AC110-120V 50/60HZ Pi:15W@120V PF>0.9, flicker less than 10%

compatiable below list dimmer:

Lutrun dimmer:

DVCL-153P

MRF2-6CL

DV-603PG

MSCL-OP153M

S-600P

S-603P

MACL-153M

CTCL-153P

SCL-153P

MSCL-VP153M

DV-600P

SFSQ-F

LEVIN Dimmer:

6672

6674

6631

6633-PLW

6633-P

6161-A

IPL06-10Z

EATON Dimmer:

DAL06P